Robust three-phase vertical milling machine with steel frame, designed and manufactured for the milling of PU blocks, to reproduce shapes of orthopaedic moulds and final cosmetic covers, for lower limb prostheses.

Its handling is simple, using a high-resolution touch screen.

Spindle transmission: through x, y axes.

During the milling cycle, the machine enclosure is inaccessible to the operator, thus protecting their safety.

Optional: the machine can be supplied in addition to the special shaft for PU foams, with a shaft designed to hold cosmetic foam covers.

Ideal for the manufacture of circular shapes: corsets, prostheses, KAFOS, AFOS, cranial orthosis, etc.

A fast and inexpensive option. No qualification or special training is required by the staff to use the Laniakea V100, or to configure the cam software.

Speed: 100mm / sec

Resolution: 0.005mm

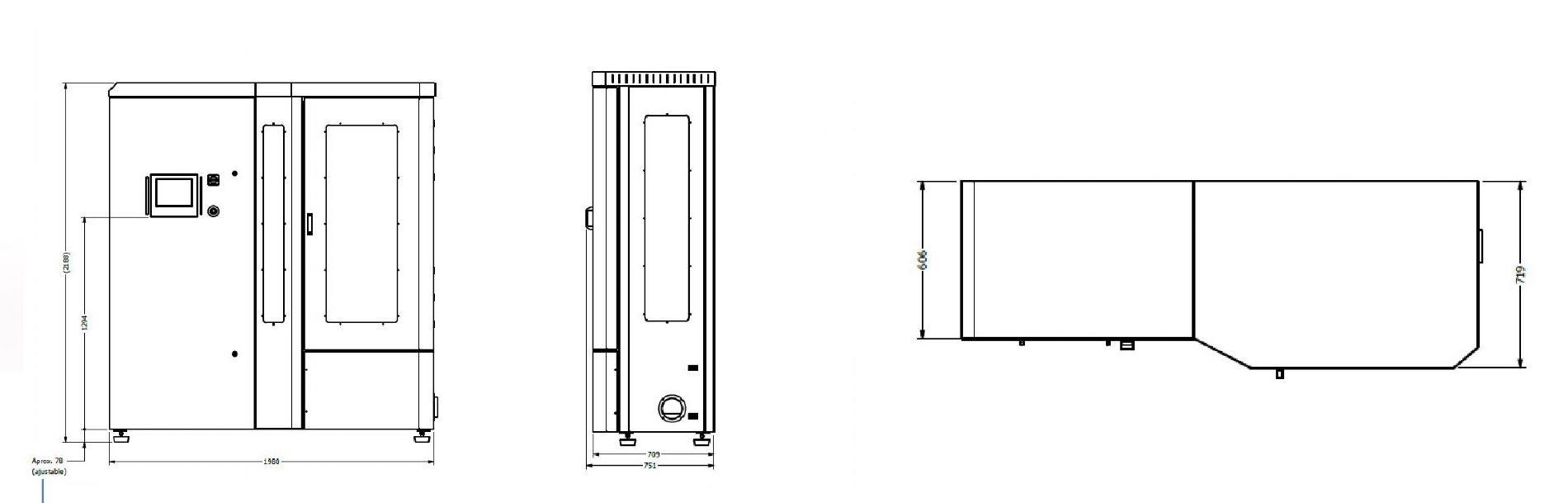

Milling capacity: 605 x 1005 mm

Milling motor: 3CV x 24.000 r.p.m.