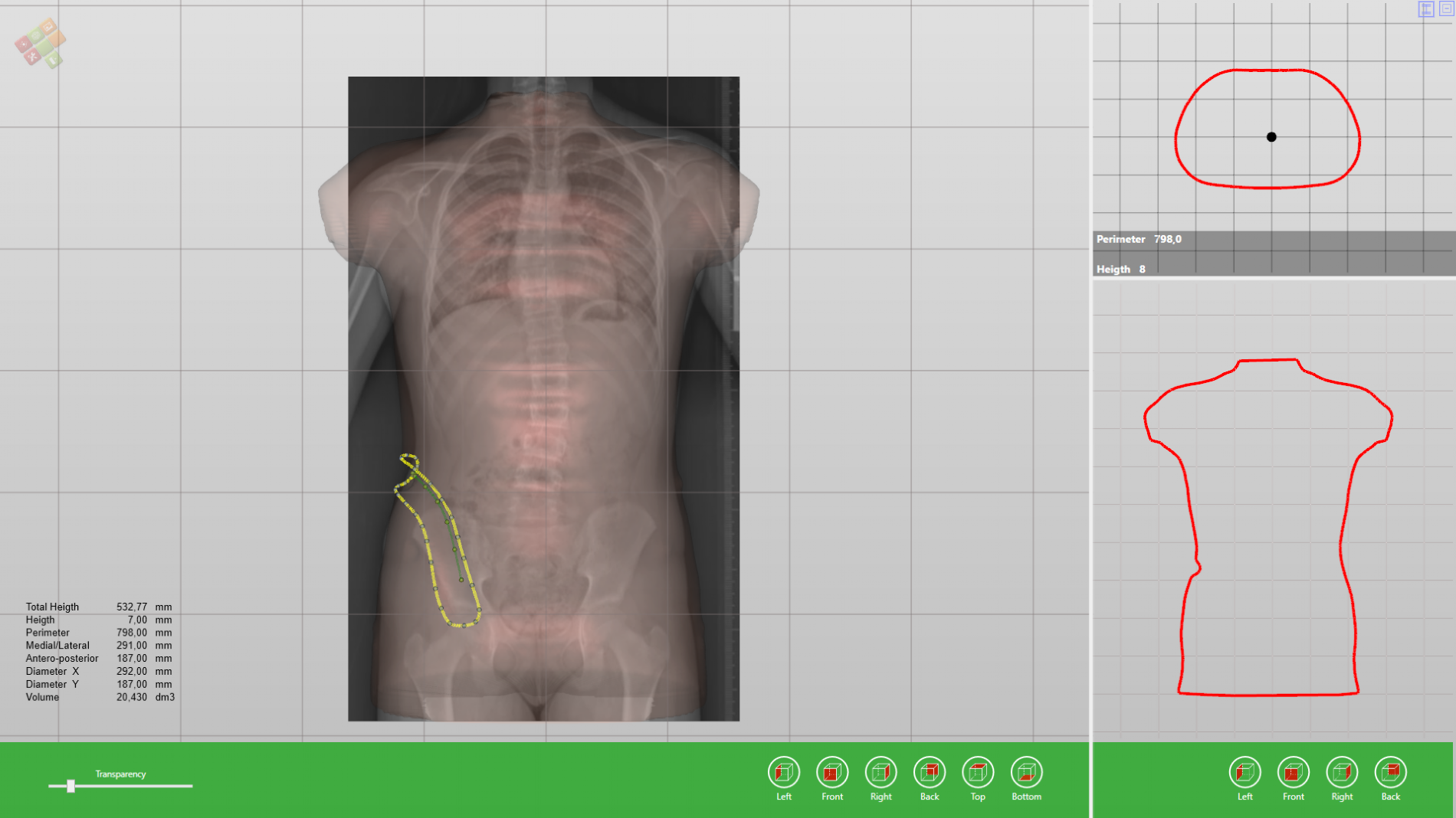

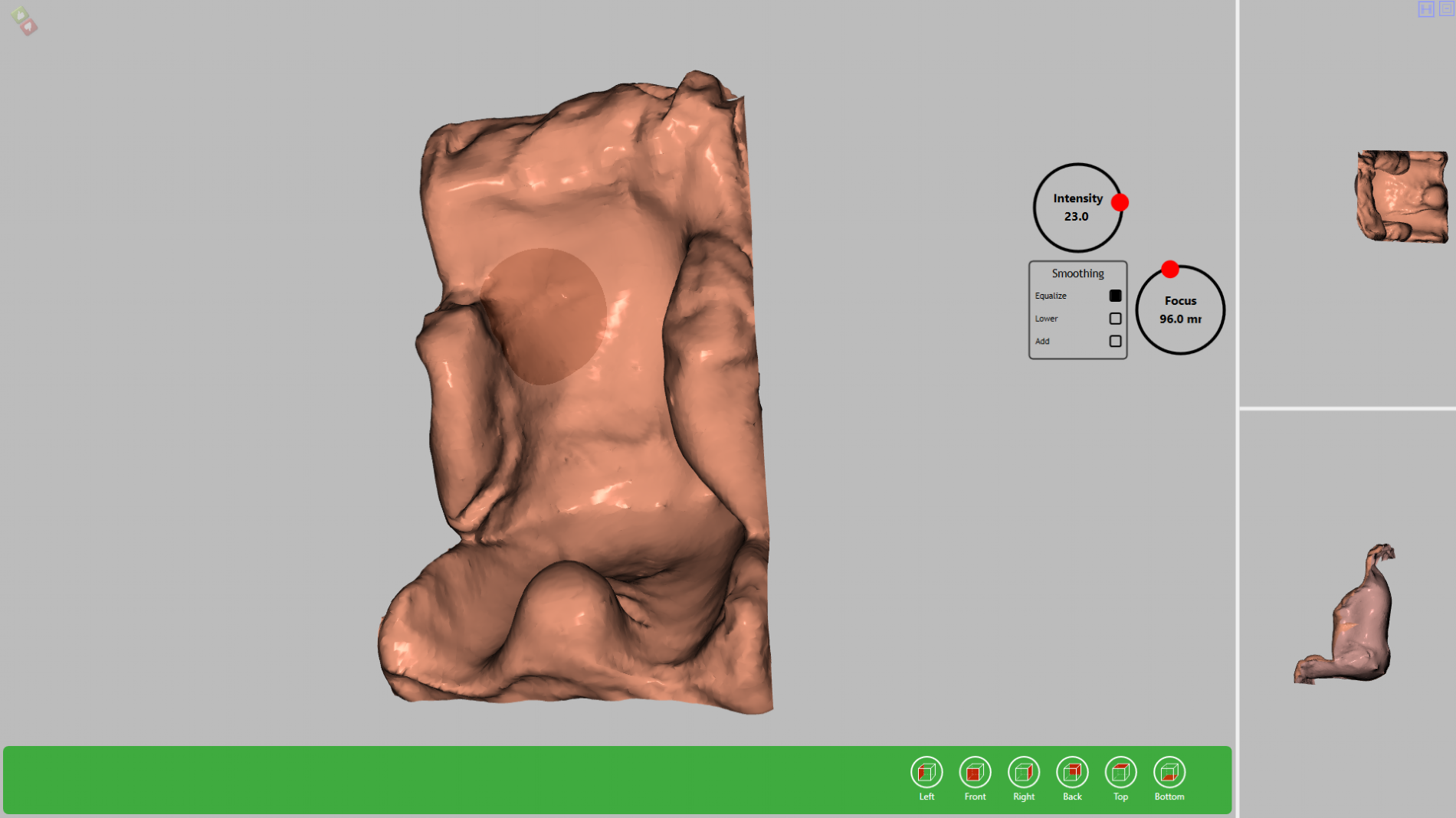

The design of the trunk, in general, is where CAD in technical orthopaedics has been most developed, it has been possible to replace the cast with the same work technique. In addition, with CAD technology, rectifications can be made that before with the traditional system were practically impossible and, most importantly, they can be edited and modified as many times as necessary.

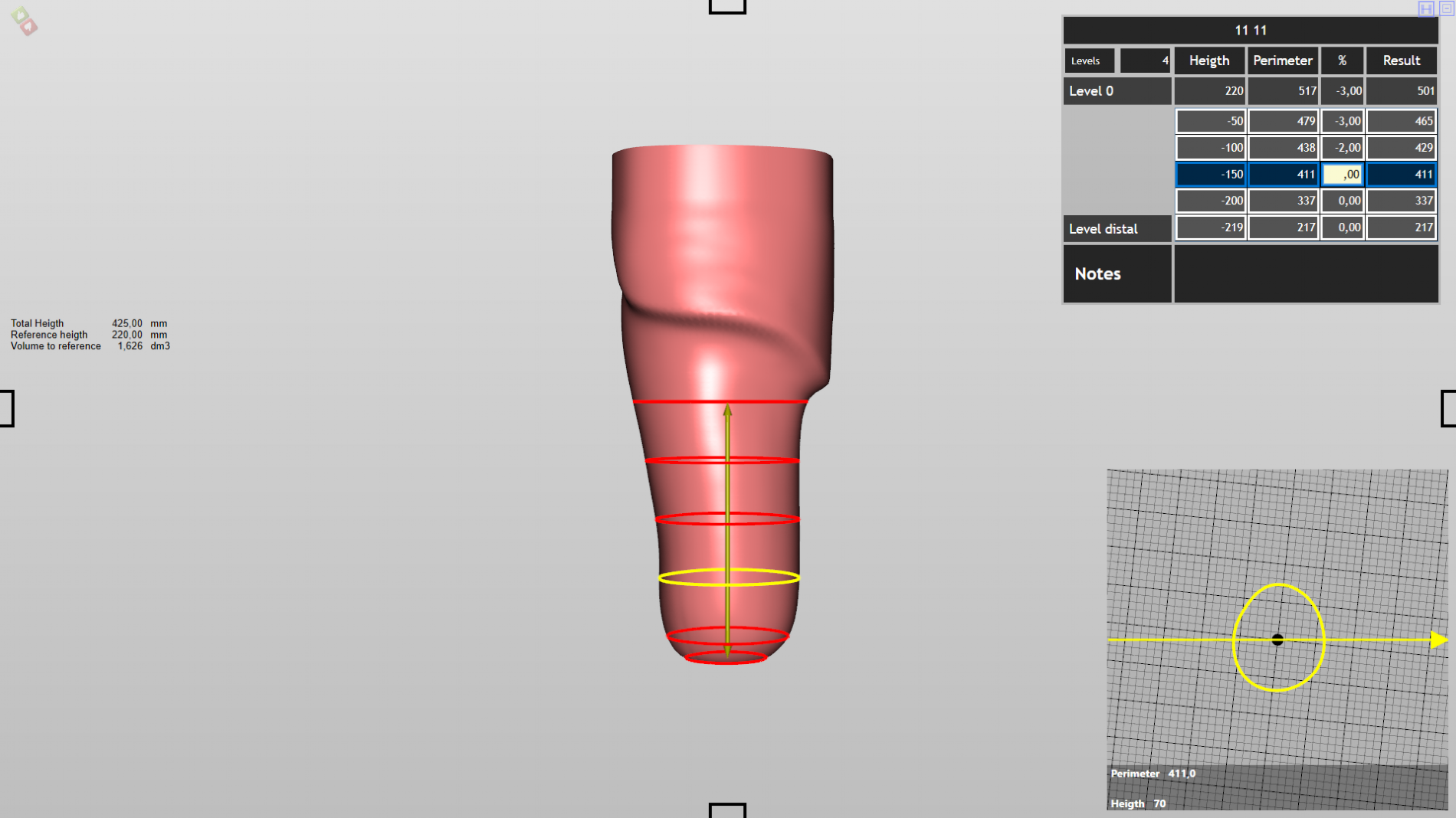

Rotate, lengthen, zoom in on a specific area, smooth, mirror, balance, etc. they are operations that can be carried out easily, obtaining precise results in reasonable times.

X-rays, photos of the patient, etc. can be incorporated, which serve as additional information, in addition to your own measurements.

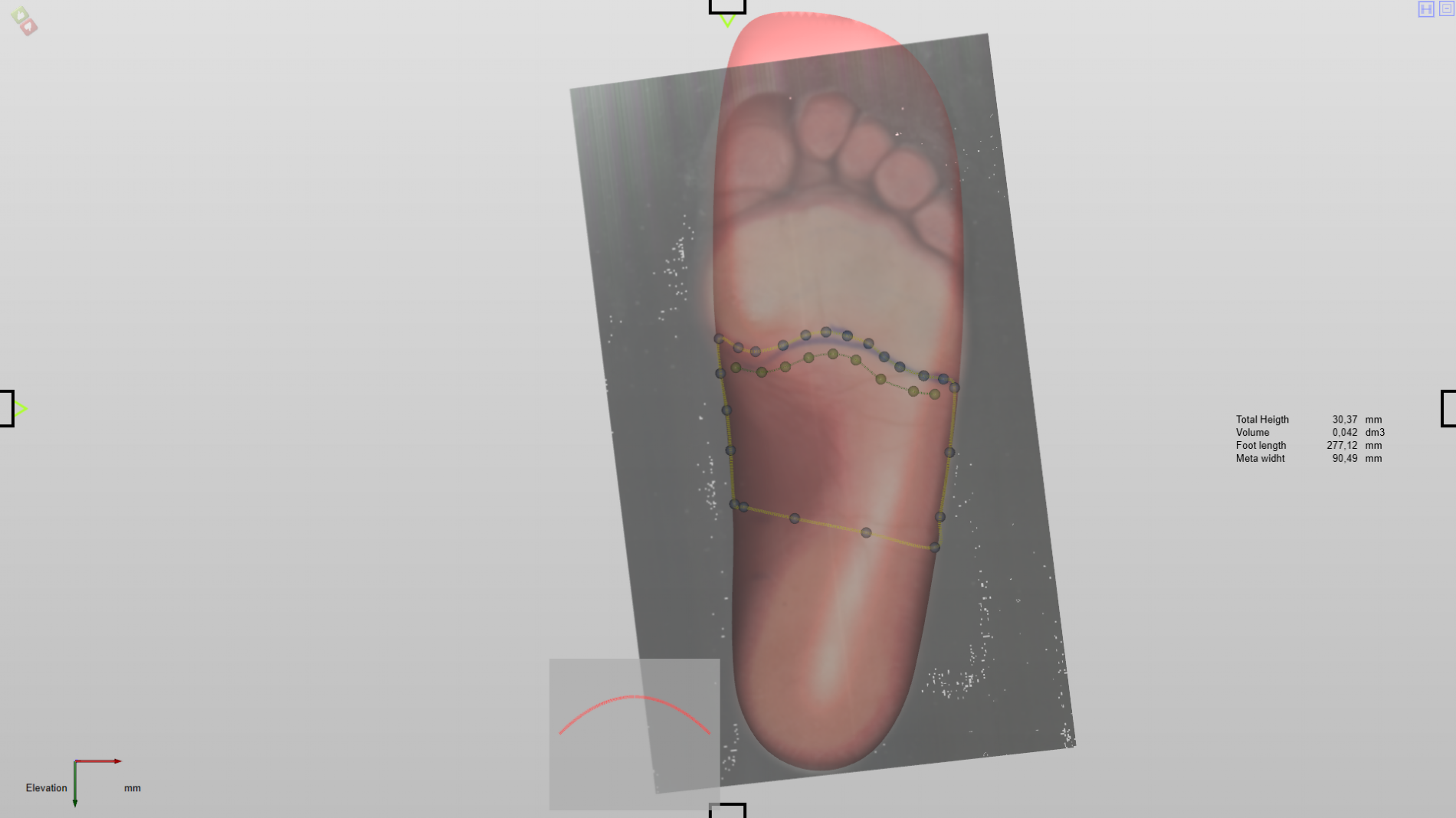

All jobs can always be carried out from a library installed in the software, modifying its measurements, lengths and perimeters; or from digitized forms directly to the patient. Both ways of working are valid, as long as the measurements are carried out correctly and with 3d scanners and precise tools.

Finally, at the end of the work, we will always have a history of everything we have done, which will allow us to analyze the results in the future, check their traceability and share the work done with other professionals.